Building an Inventory System with RFID for Retail

THE "In-Stock" PROBLEM

Todays consumers need daily fresh counts

A key component of satisfying a customer is accurate stock information by location.

It's not that complicated - and we only need to solve: What is 'in stock' by location?

But, counting products is saddled three issues:

-

Time: It is labor-intensive to update the product count. It can take a day to count a store requiring employee time when employees are scarce.

-

Accuracy: Manual counts are inefficient and inaccurate, as much as 13% off from actual values.

-

Delays: The counts are done at three-month intervals creating inaccurate inventory levels for 90 days. An estimated slippage of 3-4% month (Macy's reports), meaning your inventory is about 12% lower than expected by your next cycle.

Incorrect inventory data erodes customer confidence and turns an omnichannel approach into a cost center instead of a profit center.

RFID In the Retail Store

If your product arrives pre-tagged with RFID, you have no incremental costs to support RFID. Daily counts can be done in minutes.

Feeding your data into omnichannel systems like Shopify, New Store or Blue Yonder, you can confidently say, "We have more than one in stock at these locations near you."

Stores that implement omnichannel systems see a 5% overall improvement in sales volume. High-performers continue to grow faster and outperform low performers by 50% on a revenue per-square-foot basis. (Source: McKinsey)

RFID Retail ROI Calculator

This ROI calculator analyzes the parts/pieces of adding RFID to your inventory solution.

Open Calculator:RFID in Retail ROI Calculator_

Make a copy of this spreadsheet to play with your values. You can download it as an Excel (xls) file or log in with Google and "make a copy."

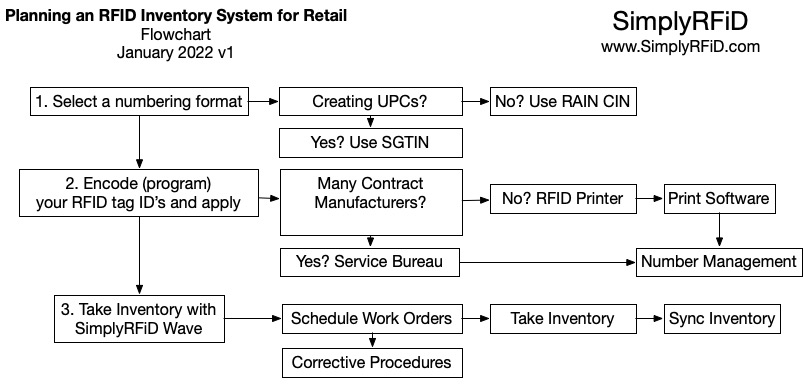

How to IMPLEMENT AN RFID INVENTORY SYSTEM

There are only three steps to implementing an accurate RFID-based inventory system for your retail stores.

- Select a tag encoding standard or several.

- Encode tags at the source (mandate), from a service bureau, or at the store level and tag your products.

- Take Inventory with SimplyRFiD Wave.

1. Select a TAG ENCODING STANDARD

Choosing an encoding format (number) for your tags is essential in planning your RFID system.

Primarily: You want to ensure your numbers are unique and ignore rogue tag data.

Secondarily: You want your tags to be fast and cheap, yet valuable. 96-bit RFID tags satisfy that need.

Finally: You want them to follow a rigid format to make it easier to filter.

There are two tag encoding standards you will want to know about:

The RAIN CIN tag format allows you to develop intelligent RFID systems to locate last-years SKU's by mfd date, identify counterfeit tags, and mark UPCs as 1st/2nds for faster sorting. The SGTIN tag format allows you to support legacy standards and 3rd party UPC barcoded products.

- RAIN CIN: The RAIN Alliance started in 2014 to make interchangeable standards for RFID. The RAIN Alliance publishes a standard for encoding tags to the RAIN CIN specification and reserving RFID prefixes for a nominal yearly fee. SimplyRFID Wave and Pogi natively support the RAIN CIN data standard with decoder masks for product SKU tables and additional data like expiration, lot numbers, and Manufacturer codes critical to your business.

AmerisourceBergen made an open RAIN CIN encoding implementation that is a perfect example of effective use of RFID for stock control, yet simple enough for daily use.

- SGTIN-96 - SGTIN (Serialized Global Trade Identification Number) is a legacy standard for converting 1970's UPC (universal product codes) "barcode numbers" into an RFID tag. Sometimes the SGTIN is referred to as an 'EPC' or 'electronic product code' to bridge the transition from barcode to RFID. Consider how SGTIN fits into your supply chain. If you use UPCs extensively, you will want to support SGTIN. SimplyRFID Wave and Pogi natively support the SGTIN-96 data standard published by GS1.

Review our RFID tag encoding guide for best practices and an in-depth guide to further planning. SimplyRFiD can help you determine an SKU encoding and filtering process that will streamline your operation.

2. Encoding your RFID tags

Once you select an encoding schema, you'll need to encode/program your tags.

For simplicity: RFID tags come with a 96-bit piece of usable data 'encoding space.' There are other options, but 96-bit is the current high-speed standard.

The tags need some number stored (encoded) to be usable.

You can put that number in there in one of several methods:

- Service Bureau / Outsourced

Attach a pre-encoded RFID tag to your finished goods. Pre-encoded tags are the best method in most manufacturing operations as tags are ready to apply as part of the finishing/QA process and don't require IT integration to work on your shop floor. Most service bureaus can provide tags pre-encoded for about a penny extra on a roll or stacked and ready-to-apply to finished goods.

Budget about 6 cents ($0.06) per ticket tag on orders of 500,000+ RFID tags. A bit more on smaller runs.

- Raw RFID tag costs in China are around 3-4 cents for 96-bit NXP UCode9 and Impinj M7xx ticket or sticker tags (November 2021) in low millions of RFID tags per run.*

- Print/encode in-house

Purchase an RFID printer like the Printronix T4000 for about $2,000. The T4000 is a quality printer for 5,000-10,000 RFID prints per-day and is perfect for USA distribution centers to produce corrective RFID tickets or as part of your in-store replacement operations.

If you plan to print in-house, you'll need software to manage your printing and numbering systems. SimplyRFiD offers 'Print Tool' as an add-on to your SimplyRFiD Pogi server.

SimplyRFiD also offers custom drivers for Linux to print-on-demand one or 1,000,000 tags with custom, readable information.

Selecting an RFID Tag

Retail will typically use two tags: The TI (Hang Tag). And, the TR800 (Sticker style RFID tag) that can be placed on shrink wrapped packaging -- like '3 pair Mens Briefs'.

If your product is super-luxury, you may go with something more extravagant and build it into a more prominent solution, possibly even re-usable tags.

We go into this a bit more in our RFID in Jewelry how-to.

Apply RFID tags using a hangtag gun with the RFID embedded in the hangtag or with an adhesive sticker to plastic wrap or product boxes.

Dual tags (EAS/RAIN RFID Inventory: Dual-tags exist but typically add expense beyond two separate RFID tags. Some retailers have successfully built this into a re-usable plastic theft deterrent tag and recycled them.

The price of a hangtag or sticker RFID tag is similar.

3. Taking Inventory with SimplyRFiD Wave

Our Wave handheld RFID reader is a low-cost, fast way to take inventory. It's a complete turn-key RFID inventory system for less than $2,500, well-equipped.

Wave pulls inventory lists, SKU tables, and work orders from SimplyRFiD Pogi for reliable inventory.

Taking Inventory

- The store manager issues a work order.

- Wave loads your expected inventory list.

- Use one or several handhelds to scan the store and upload results to the SimplyRFiD Pogi server.

- The store manager reviews the inventory results and accepts or rejects the new inventory.

Sharing Inventory Data with SimplyRFiD Pogi

Once your inventory is confirmed, SimplyRFiD Pogi integrates to your omnichannel systems like Blue Yonder, Shopify, Quickbooks, and New Store.

You can get started with your RFID Inventory System by giving us a call. We'll guide you through every step.

Bonus Reading

Here are some references/statistics on RFID in Retail:

-

The drive for inventory accuracy comes not just from omnichannel but from satisfying customers needs when they can easily shop at-home or elsewhere to locate their items.

-

Gartners November 2021 retail excellence report only made three suggestions, one of them: "Develop capabilities to improve product-level store inventory accuracy by amending counting processes and investing in RFID technologies." - Gartner Retail Excellence 2021