What would you do if inventory turnover increased 10x?

Managing Inventory Turnover to 10x Your Business

How would your business be different if you sold 10x the number of items you sell today? What would you need to change to deal with that volume?

Think about this. Imagine your new business. The fun. The problems.

What do you sell?

What did you imagine when you thought about selling 10x the amount of product? More space? Bigger store? More employees?

How about none of that.

The issue is: There is only so much great real-estate for sales. And, only so many great people to hire and manage. You have to locate it. Rent it. Hire for it. Manage it.

Can you tune your current business? Does technology apply?

Inventory turnover is 'how many times you sell a bottle of Gatorade and how many you needed to keep stocked' to sell that many.

Selling in the physical world, your real estate is precious. Pick the best location. Move the most product. Be efficient.

Inventory turnover is only relevant based on where you sell (location) and the product sold. And inventory turnover is all about efficiency, and making more profit.

How do you get 10x inventory turnover?

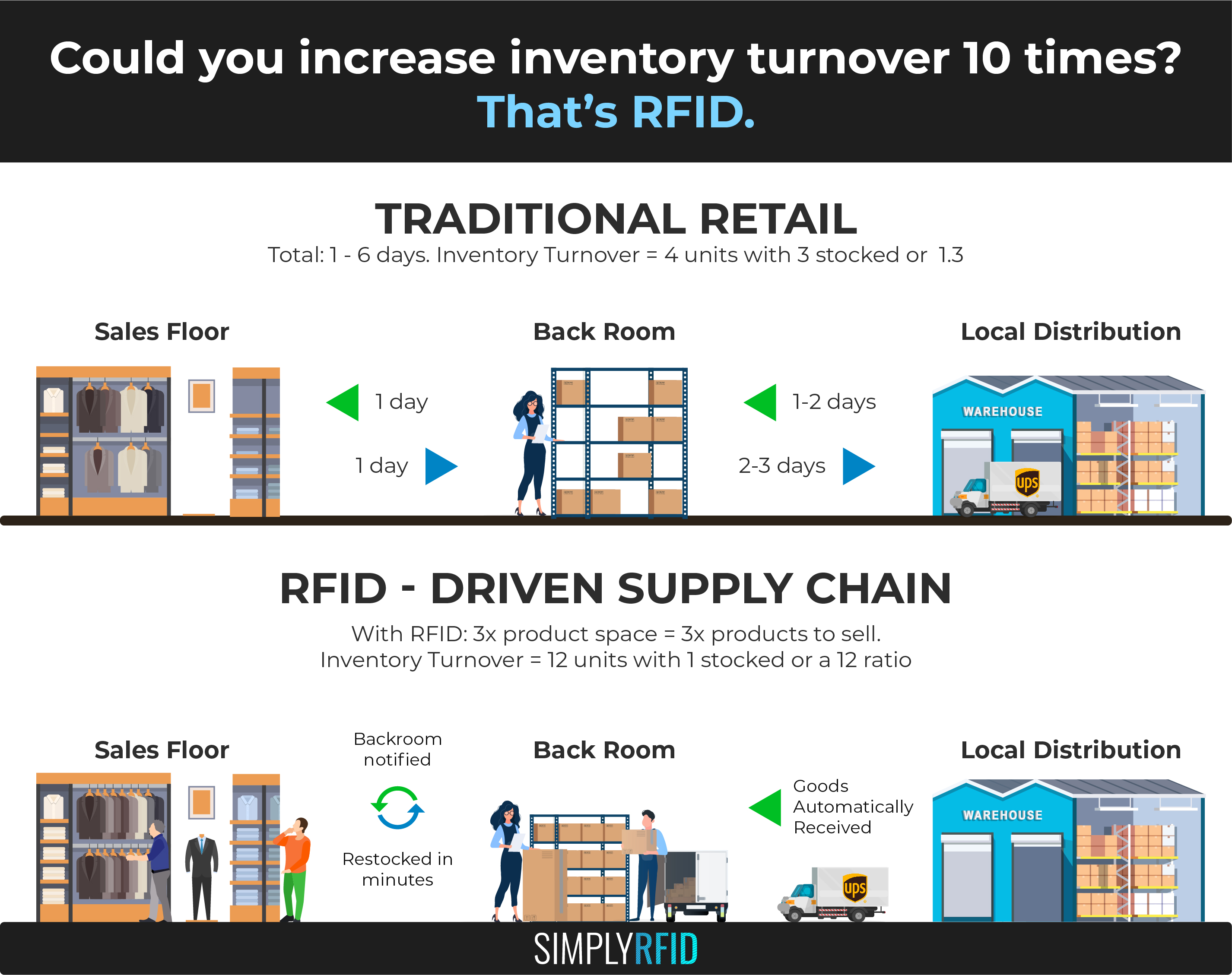

Let's say you have a clothing retailer in an expensive foot traffic area. On average, your turnover is '4'. That means in a 30-day window; you turn your inventory once a week.

Mathematically: Turnover = Sales (4 units) / Inventory (1 unit).

But wait. If you are selling clothes, do you just have one 'Small Pullover?' No. You have three of each size.

Now: Turnover = 4 units / 3 units or 1.33 - not 4.

So, your number is 1.33. Your competitor across the aisle has an inventory turnover number of 3. How are they doing it? Sell more units? Lower quantity on-hand?

To increase turnover, you need more selection available in the same square footage. More specifically, you need to look at your turnover rate and your sales per square foot.

Turnover represents efficiency. Efficiency = more profit. The higher the number, the more efficiently you run your operation in given square footage and advertising budget. RFID is a 10x multiplier in the way you can and will run your business.

More Selection, Smaller Space

Lowering Inventory

With RFID, when an item is removed from its sale location, the item is automatically replenished.

Sales per Square Foot = Sales / Square Feet.

With RFID, you can stock one of each item. Increase the total types of items to increase overall sales and increase selection without increasing store space. Additional items can be stored nearby and replenished on-demand. The same piece of real estate can sell 5x the amount it sold before because you don't need to stock three units of every item, size, and color to ensure customers find the product they want.

Additionally, sales won't be lost when inventory is miss shelved, or not placed on the display floor, or sitting in incoming shipping boxes, unreceived.

Before RFID

- Customers select products.

- Items are taken to fitting rooms or left in various locations throughout the store as consumers change their plan. Items not selected are left in a put-away pile.

- Items are placed back onto the sales floor later that day or in a few days.

- Sold items are ordered from distributors for replenishment.

Meanwhile, during a sale, the proper color and size are stuck in the fitting room floor, but the customer doesn't buy because they could not find it.

After RFID

- Customers select products. RFID triggers a notification that the item has been removed from the rack. The backroom team starts a restock.

- Items are taken to fitting rooms or left in various locations throughout the store as consumers change their plan. Items not selected are left in a put-away pile. RFID notifies the backroom team; there are items available to restock if a customer is looking for a particular item.

- The staff know exactly where every style and size is located via sensors in the backroom, try-on, and floor. Staff carry an always-on RFID reader that tells them when they pass items in the incorrect location, allowing them to improve their product location continuously.

- Out of stocks are sent automatically to distributors. When packages arrive, they are automatically added to inventory. The staff know which 'sealed box' contains the needed items and can place stock onto the floor for sale.

Getting Started

Take a look at our RFID Cookbook for ideas on how you can increase your sales. Getting to 10x will require a significant change in how you run your business.

But, for $299 a month, you can add RFID to your daily operation. If this makes you 5% more efficient (taking a daily inventory in minutes vs. a quarterly inventory in days) and your yearly sales are $1,000,000, you'll save (or make) $50,000 on a $1,200 yearly investment. And, customers will recognize you as the place that has in-stock goods and better selection.

Footnotes on using Inventory Turnover to tune your business

There are several other cool ways to calculate inventory turnover. For instance, COGS / Average Inventory. Using COGS allows you to measure multiple items, but it's hard to laser-focus on a single item.

Let's say your store sells $1,000,000 a month. Your average inventory is $500,000. Then your # is 2. But, it's difficult to tune a single item and get great at it. However, applying RFID will allow you to reduce inventory by about 30% and still hit the same COGS for pennies.