What's the best way to tag a metal drum with RFID?

Most RFID tags need about a half-inch of separation between the tag and the metal to get any read range. There is no way for RFID to penetrate metal, so placing tags inside metal and expecting to get a read is out of the question; however, reading a tag placed directly on metal is becoming easier.

Absorption

Metal reflects RF, so no RF can pass through a metal sheet. Most RFID tags, when placed directly on metal, will have reduced read range. This read range can be improved by using a spacer to put about a half-inch of space between the metal and the RFID tag. Some tags are designed to be explicitly placed on metal. Metal-mount tags use their metallic backing to create an isolated antenna system.

These tags cost more due to the complexity of the tag.

Placement

Standard RFID tags may be used in combination with a foam spacer designed explicitly for use with the tags. Spacers are often large and fragile. Spacers can be used when shipping palletized loads.

Pro-Tips

- Expected RFID Read Ranges: Standard RFID tags will have a read range of inches up to a maximum of 1'. This range can be extended up to 10' to 15' by using a spacer. Metal-Mount Gen2 hardened tags will read a minimum of 10' up to 15' when optimized.

- Expected Costs of RFID Tag: Non-programmed Metal-Mount RFID tags cost as much as $3.74 each, quantity one, and as little as $1.67 each over 1000. Pre-programmed Metal-Mount RFID tags cost approximately $2 each on quantities over 1000. Spacers for standard RFID tags will add $0.30 to the cost of each label.

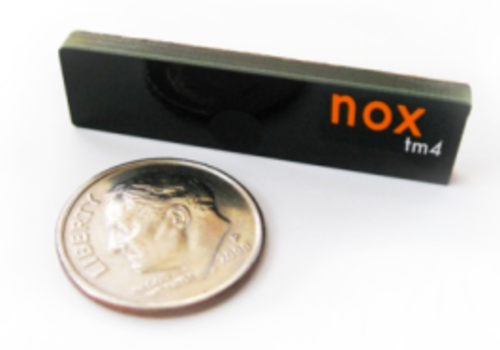

- What RFID tag sizes are there? Metal-Mount RFID tags are now as small as 38mm x10mm x2.8mm.